Product Introduction

Three reasons why people choose Boscher mini

Point ① Improve productivity with powerful washing of one foot in just 5 seconds

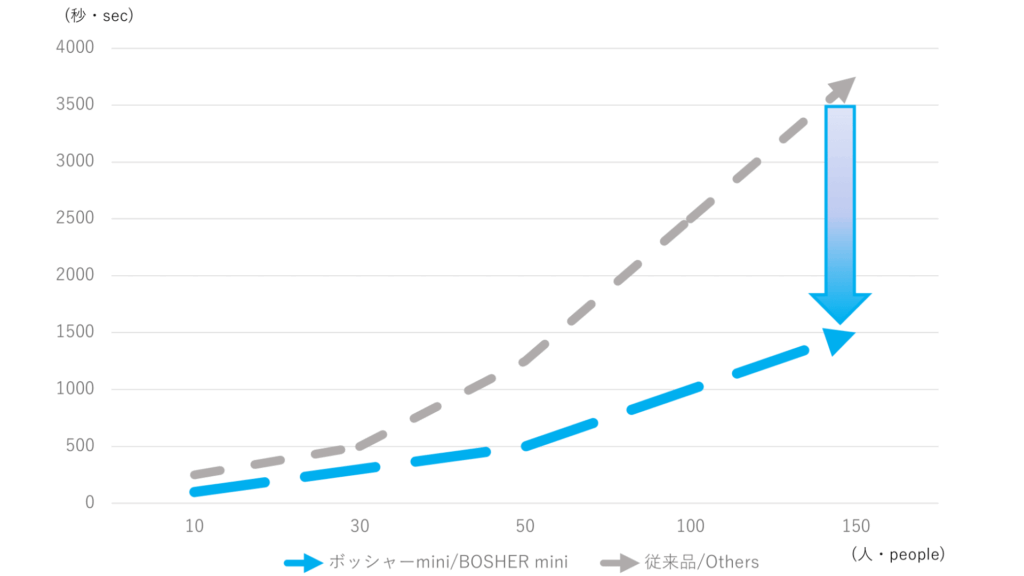

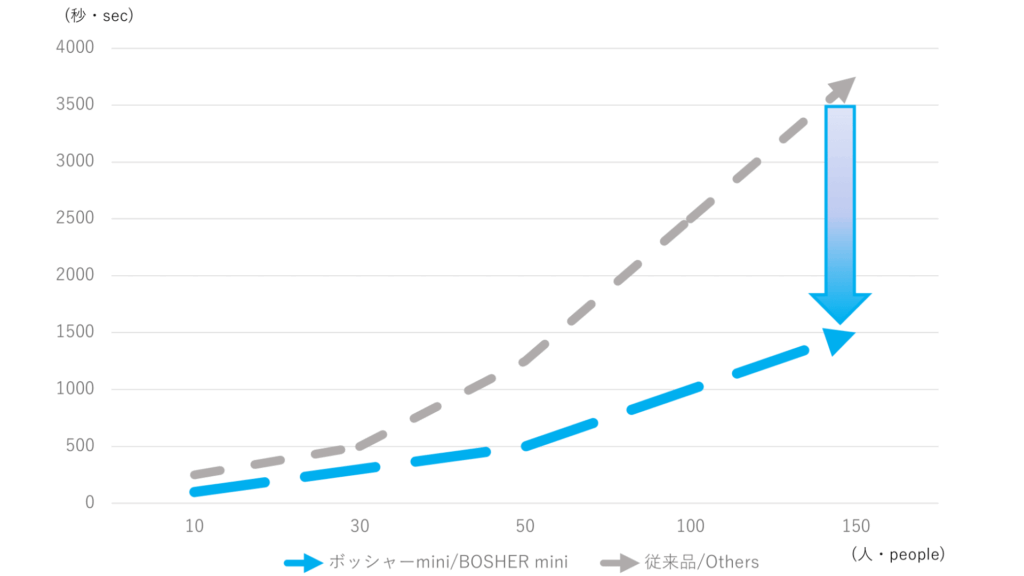

With the Boscher mini, you can wash one foot in just five seconds, and the time difference compared to washing by hand is clear.

It also eliminates individual differences in dirt removal, eliminating the need for personal instruction and the need for re-washing, improving productivity.

Increase productivity with just 5 seconds on one foot

Save up to 40 minutes

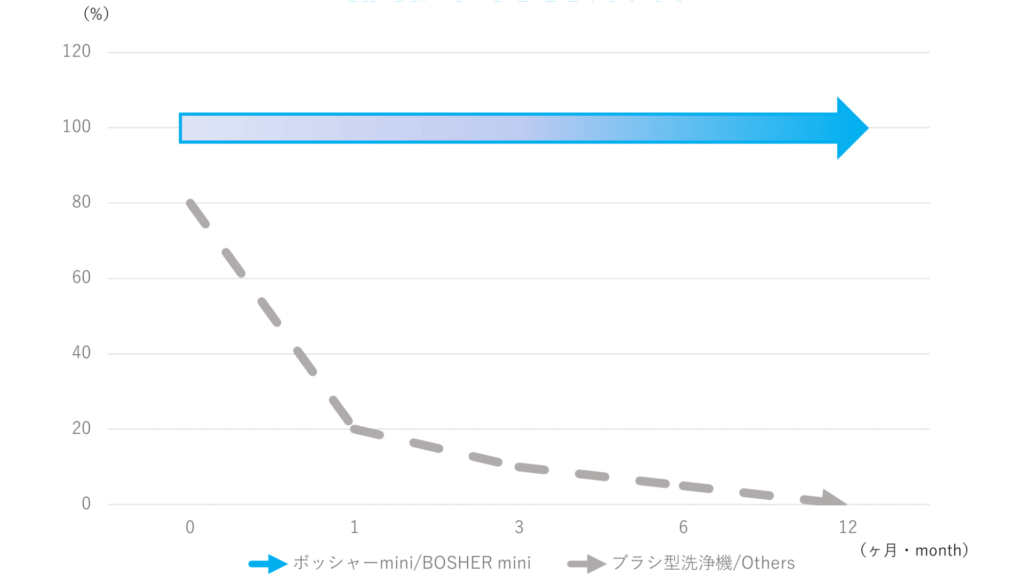

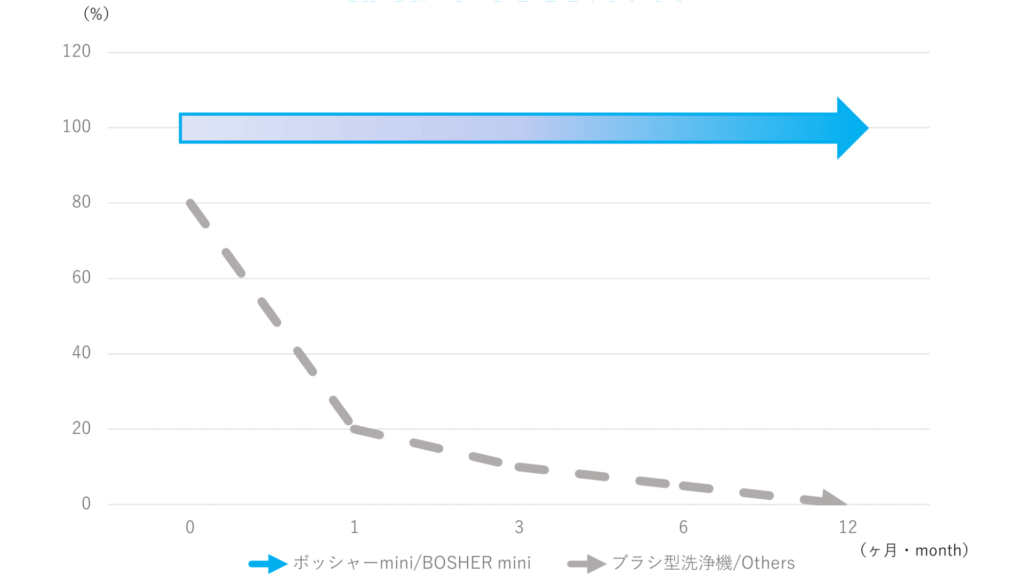

Maintains 100% cleaning performance

Cleaning power that never fades

Point ① Improve productivity with powerful washing of one foot in just 5 seconds

With the Boscher mini, you can wash one foot in just five seconds, and the time difference compared to washing by hand is clear.

It also eliminates individual differences in dirt removal, eliminating the need for personal instruction and the need for re-washing, improving productivity.

Increase productivity with just 5 seconds on one foot

Save up to 40 minutes

Maintains 100% cleaning performance

Cleaning power that never fades

Point ② Easy installation and maintenance

With a minimal design of just 50cm in length and width, installation takes just three steps.Since the number of parts is small, even customers who do not have a construction or equipment specialist can use it with peace of mind.

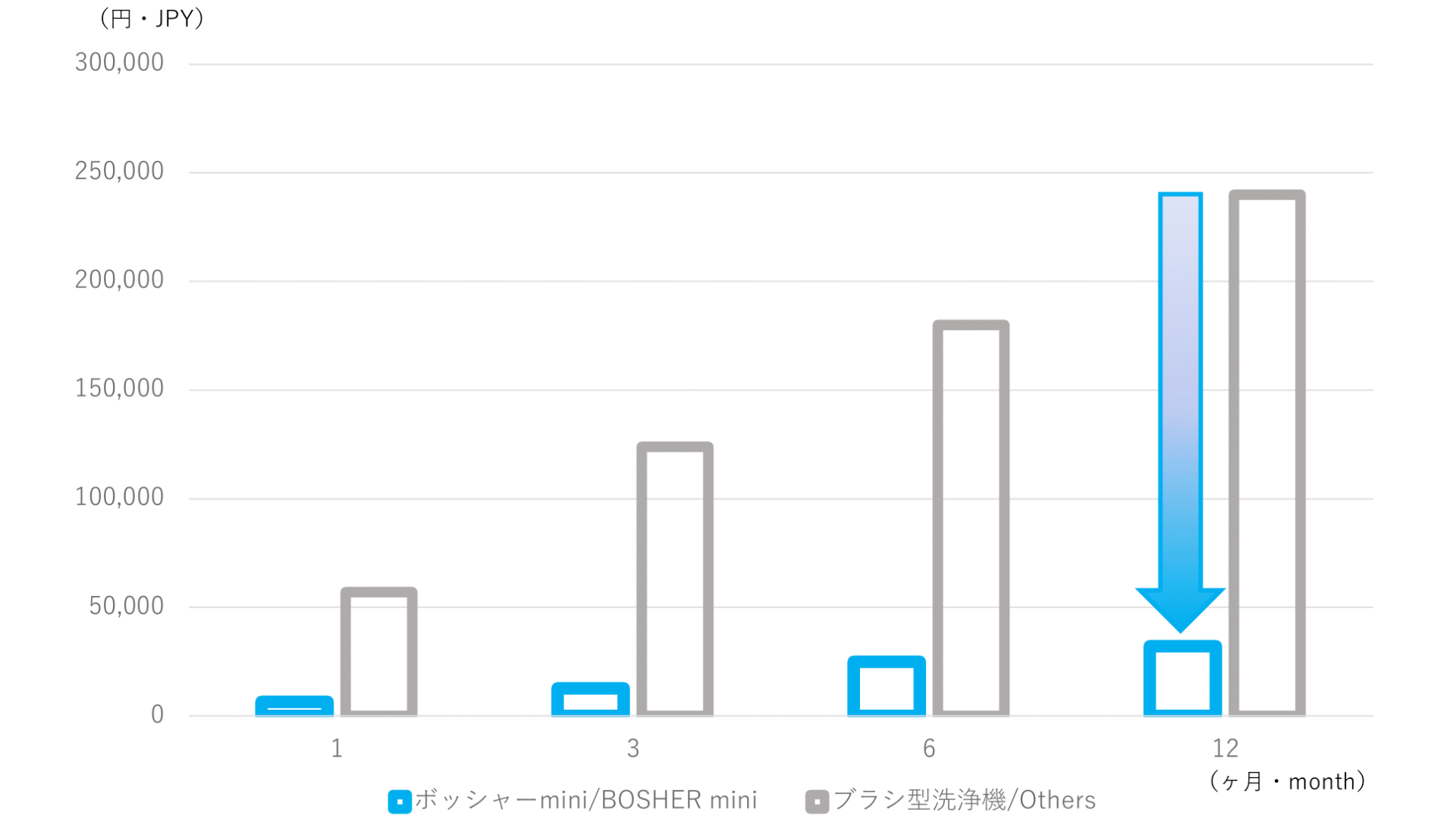

Point ③ Maintenance costs are now 1/5 of what they used to be

The Boscher mIni does not use brushes or electricity, and can reduce utility costs, consumable costs, cleaning labor costs, etc. by up to 75% compared to conventional products.

Running cost reduced to one-fifth of conventional models

Low maintenance cost with no consumables required

Point ④ Universal design that is easy for anyone to use

The Bosscher mini complies with universal design. It does not require complicated operations and can be used intuitively even by foreigners and beginners. Its simple design, focused on visibility and operability, makes it easy for anyone to use.

► Air and water mix cleaning

(1)By mixing air and water, we have achieved high hitting power and water saving.

(2)The ratio of air to water can be adjusted to accommodate a variety of types of dirt.

(3)Since no brushes are used, the cleaning power does not decrease due to wear, and strong cleaning can always be achieved stably.

► Ultra-clean environment

(1)The residue left over from cleaning will collect in the tray at the bottom, so you can simply remove it and dispose of it.

(2)There is no need to clean dirt off the brush, as with conventional brush cleaning methods.

(3)The roller part and cover can be easily removed and washed after removal.

(4)There are almost no protrusions inside the tank, making it extremely easy to clean and maintain.

(5)Since it is made of stainless steel and does not use electricity, the entire unit can be washed with water.

► Compact size

(1)Despite its compact body, it can accommodate short and long boots of all sizes.

(2)An erector pipe can be used at the bottom of the main body, and the shape can be changed according to needs.

► Ensuring safety

(1)Handrails that allow passengers to support themselves with both hands are standard equipment.

(2)It is designed to be shoulder-width and have a low center of gravity, and measures are taken to prevent it from tipping over.

(3)Since it does not use electricity, there is no risk of electric leakage or electric shock.

► Product Specifications

| Model | BS-1 |

| External dimensions | W400 × D450 × H860 mm |

| Weight | 20kg |

| Material | Stainless steel |

| Air consumption | 0.1 ~ 1ℓ / once When using air blow: 30ℓ / once (3 seconds used) |

| Supply water | Tap water |

| Water usage | 0.12 ~ 0.22ℓ / 1 second |

| Washing Time | 5 seconds ~ / 1 time |

► Product Specifications

| Model | BS-1 |

| External dimensions | W400 × D450 × H860 mm |

| Weight | 20kg |

| Material | Stainless steel |

| Air consumption | 0.1 ~ 1ℓ / once When using air blow: 30ℓ / once (3 seconds used) |

| Supply water | Tap water |

| Water usage | 0.12 ~ 0.22ℓ / 1 second |

| Washing Time | 5 seconds ~ / 1 time |

► Company Information

| Trade name | Bunshi Japan Co., Ltd. |

| Founding | Founded on February 1, 1957 February 4, 1982: Incorporated |

| Capital | 22 million yen |

| Representative Director | Shusuke Fujimura |

| Head office location | 2-3-7 Shimizu, Shunan City, Yamaguchi Prefecture, 746-0015 TEL: 0834-62-2575 FAX: 0834-62-4283 |

| Number of Employees | 122 people (including part-time workers) *As of June 30, 2025 |

| Business content | ● Development, manufacturing, and sales of cleaning and sanitation machinery for food factories ● Planning, manufacturing, and sales of various packaging materials, including general packaging materials, food containers, and film packaging ● Food packaging planning and design ● Food hygiene consulting, including support for obtaining ISO, HACCP, and other certifications ● Pest control (Earth Environmental Services agency) ● Development and sales of cloud services ● Manufacturing and sales of folding cartons |

| Bank | Saikyo Bank (Tomita Branch) Shoko Chukin Bank (Tokuyama Branch) Hiroshima Bank (Tokuyama Branch) Yamaguchi Bank (Tondaa Branch) |

| Sales Office | Shunan Sales Office (Head Office) Shimonoseki Sales Office Achisu Sales Office Hiroshima Sales Office Fukuoka Sales Office Tokyo Sales Office Access information for each office |

| Major Clients | Marukyu, Coop Yamaguchi, Sunlive, Fujimitsu, Fukagawa Poultry Farm, Akigawa Farm, Yamaguchi Prefectural Agricultural Cooperative, Earth Environmental Services, etc. |

| Major Suppliers | FP Corporation, Chuo Chemical Industry, CP Chemicals, Rispack, Denka Polymer, Fukusuke Kogyo, Earth Environmental Services, etc. |

| Main Clients | Marukyu, Coop Yamaguchi, Sunlive, Fujimitsu, Fukagawa Poultry Farm, Akigawa Farm, etc. |

| Group Subsidiaries | ● Parts Kogyo Co., Ltd. (Stainless steel and sheet metal processing, manufacturing) ● MyStairha Co., Ltd. (Systems, cloud software services) |